Blister and injection molding are two commonly used manufacturing processes for producing plastic products. While they both involve shaping plastic materials, there are several key differences between the two methods.

The production process of blister and injection molding is the first distinction to be made. Blister products are made by heating a plastic sheet and then suctioning it onto a mold, shaping it through a cooling process. On the other hand, injection molding involves applying pressure to a molten plastic material which is then injected into a mold and cooled to form the desired shape. This difference in production process affects the quality and characteristics of the final product.

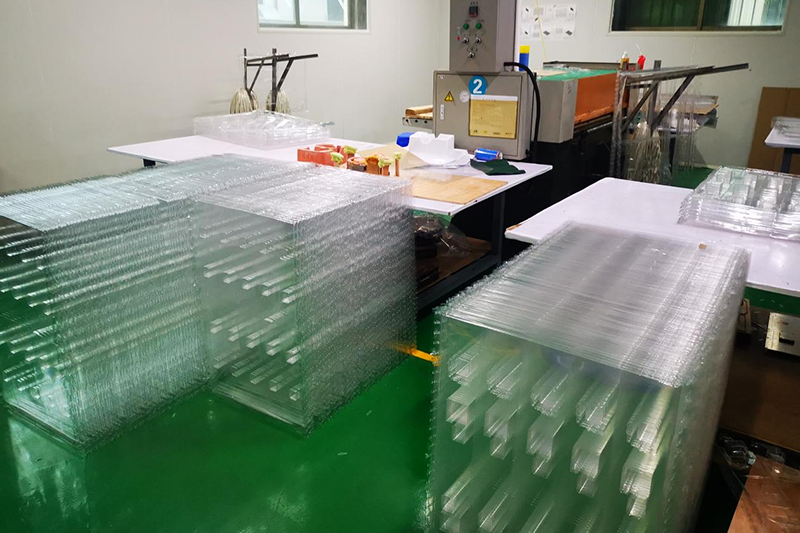

Another difference lies in the types of products that can be produced using blister and injection molding. Blister molding is commonly used for electronic products, toys, stationery, hardware accessories, and packaging materials such as plastic boxes, blister shells, trays, and covers. Injection molding, on the other hand, is often used for larger, more durable products such as logistics trays, mobile phone cases, computer cases, plastic cups, and mouse cases.

The production cycle is another aspect where blister and injection molding differ. Blister production has a shorter cycle compared to injection molding. Blister products can often be produced in larger quantities simultaneously using multiple molds, while injection molding typically involves the use of a single mold to produce multiple products. Furthermore, blister products do not require any separate cutting or punching, which further reduces the production time and cost.

In terms of practical application, blister packaging is mainly used for product turnover and packaging purposes. It provides a protective and visually appealing packaging solution for various industries. Injection molded products, on the other hand, are more commonly used for warehousing and logistics purposes. They are highly durable, easy to clean, and have a long service life. Injection molded logistics trays and other products are widely used in the transportation industry and are commonly found in logistics centers due to their large carrying capacity.

In conclusion, the difference between blister and injection molding lies in the production process, types of products, production cycle, and practical applications. Blister molding is suitable for smaller, more lightweight products and offers a shorter production cycle, while injection molding is better suited for larger, more durable products with a longer production cycle. Both methods have their own advantages and are widely used in various industries to meet different product requirements.

Post time: Jun-19-2023